Medical Gases

Medical Gas Engineering

Medical Solutions

More than 10 years of experience, Infinity Technology has gained confidence from several government agencies and private agencies of partners thanks to high quality services in medical gases piping network engineering.

Infinity Technology offers a complete range of equipment for the delivery of medical gases to the patient room or the operating room. We can also ensure the installation of the medical gas piping network, in all types of healthcare facilities.

Our formulation experts develop a comprehensive understanding of your final applications and help find patient-centered solutions for a wide range of medical indications.

We help accelerate the development of products that transform patient care by addressing unmet medical needs, improving quality of life and making healthcare more accessible.

Training

Medical Gases and Installations

We’re helping to educate and inspire a new generation of healthcare professionals, across many different hospital functions. See how surgical procedures can be more interactive than ever before.

Infinity Technology for engineering works have an in-depth understanding of the issues facing healthcare professionals and their industry. When you appoint us to carry out your medical gas installation or you are safe in the knowledge that our dedicated project team will deliver an integrated service with the workplace.

Experienced medical gas installers and suppliers of medical gases

Our experienced medical gas installation team work seamlessly alongside other contractors on-site to ensure any pipe work remains a safe distance from your other services. We are also suppliers of medical gases and offer a medical gas supply service to suit your specific requirements.

Because every situation is unique, we customize every single project we undertake to suit your requirements.

A medical gas piped system is designed to provide a safe, reliable and competent method of delivering medical gases, medical air and surgical air from the source of supply to the relevant terminal unit. This is done by way of a medical gas pipeline distribution system. All medical gas installations are regulated and conform to specific standards of design and construction by the medical gases industry. Medical vacuum is also provided by means of a gas pipeline system for both medical and dental patient use. In order to control occupational exposure to waste anesthetic gas and agents, a gas scavenging disposal system is in operation.

It is crucial to make sure that there is no possibility of a cross-connection between any medical gas system and that all the parts of each medical gas system, where connections can be made by users, are gas specific.

During the fitting stage of medical gas, comprehensive tests are carried out to establish that there is no cross-connection of the medical gases. Medical gas systems may be increased to those departments where respiratory equipment or surgical tools are serviced. These include electronic and biomedical equipment workshops and sterile services departments.

Cylinder Manifolds

Oxygen, Nitrous Oxide and Carbon Dioxide can be supplied by 3-fold cylinder manifolds or by a liquid oxygen tank (V.I.E.) and a 2-fold cylinder manifold with a Dräger Gas Control Station as the core of the system.

Cylinder manifolds are an important element of gas management in hospitals. They ensure the supply with medical gases and control the gas pressure. The core of the system is the Gas Control Station.

Area Control Units

All clinical areas need to be controlled individually by Area Control Units. This includes pressure gauges for each gas and alarms for pressure deviations as well as lock-off valves and emergency inlet points.

Vacuum System

Vacuum is indispensable for surgical application (wound field aspiration) as well as bronchus suctioning in anesthesia and intensive care treatment. Dräger vacuum systems with triplex or quadruplex pumps fulfill the ISO 7396-1 and match all requirements in terms of safety and efficiency.

Compressed Air System

Medical air systems for breathing purpose (4/5 bar) as well as for surgical tool air (7/8 bar) must fulfill the ISO 7396-1, breathing air must also comply with the European Pharmacopoeia. Dräger medical air systems combine proven design, safe operations, and efficient reliability.

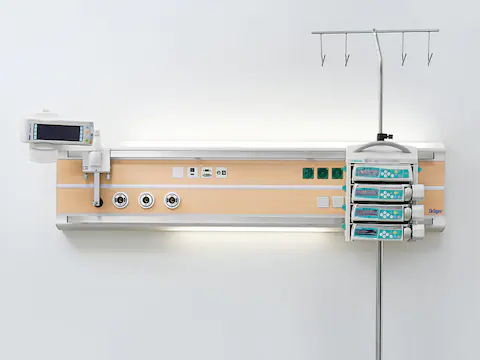

Bed Head Unit

The wall supply units can be configured in different ways for the most varied care requirements. They can be perfectly combined and enable a consistent design concept that goes beyond the individual room. A large selection of decors and colours, as well as various lighting options, also contribute to providing a healing environment.

Surgical Ceiling Light

In the operating room, the right illumination is essential for success. The Polaris® 100/200 surgical illumination systems provide cool light with natural colours and rich-contrast for thousands of hours of carefree operation without straining on your hospital‘s budget.

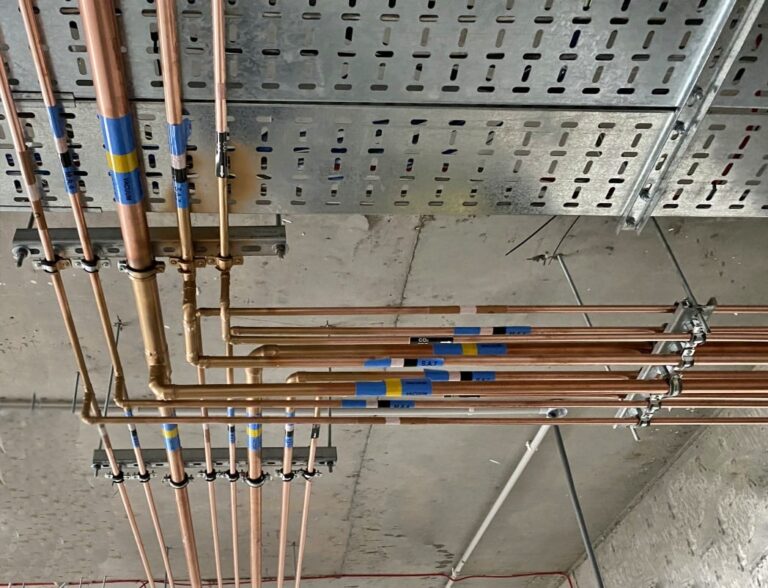

Distribution System

The role of the pipeline distribution network is to send the medical gases and vacuum where they are needed. The safety of the entire hospital is compromised without a professionally designed, installed, and maintained distribution system. Accordingly, Dräger only ever uses thoroughly tested copper piping with a defined degree of purity that has been approved for medical applications in accordance with EN 13348.

The quality and performance of the entire system is ensured by professional system planning in accordance with Dräger design guidelines and international standards as well as extensive testing and high-quality installation (e.g. inert gas soldering).

Gas Terminal Units

When planning your Gas Management System, we make sure that the terminal units are located exactly where they are needed to ensure a patient supply that is both ergonomic and suited to the clinical workflows. Different gases are needed in different hospital areas, depending on the clinical discipline and application, and the number of units provided must correspond to the processes and machines used there. Dräger has been building world-renowned terminal units for more than 40 years and supplies connections in line with DIN and British Standards, as well as other international types.

Oxygen Generator

Oxygen PSA Generators separates oxygen (O2) from compressed air utilizing pressure swing adsorption technology. Compressed air, which consists of approximately 21% oxygen and 78% nitrogen, is passed through a bed of zeolite molecular sieve (ZMS). The sieve preferentially adsorbs N2 and moisture over O2 allowing the O2 to pass through as a product gas at pressure.

The Alarm Management System

It makes sure that technical and clinical personnel are kept informed about the status of the central gas supply at all times. It monitors the GMS in all areas and records all signals such as operating and emergency alarms. Analogue operating values (e.g. pressure and flow rate) can be easily integrated.

All information is clearly displayed on LED, text, or touch-screen monitors, which means that messages and measurement values are always available exactly where you need them. It is also possible to access all information via your internal network and store it for your documentation. Furthermore, relevant alarm messages can be forwarded via SMS and e-mail so that you are always immediately informed of a fault wherever you are and can react quickly.